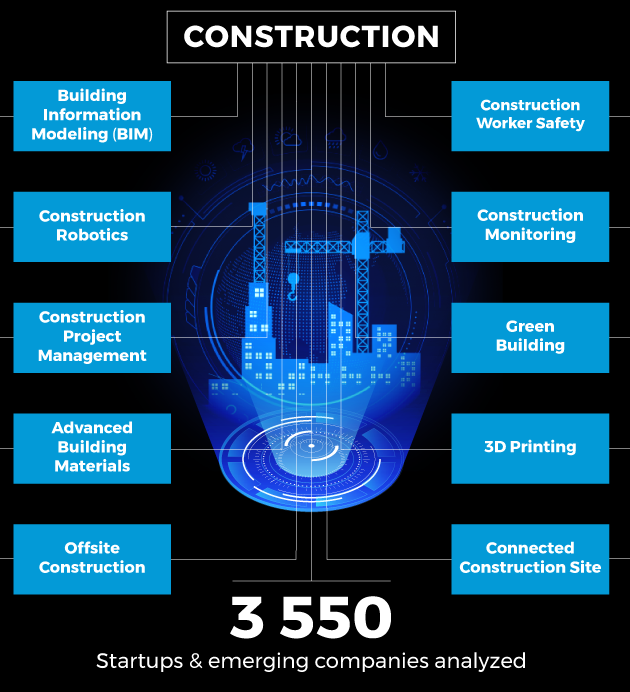

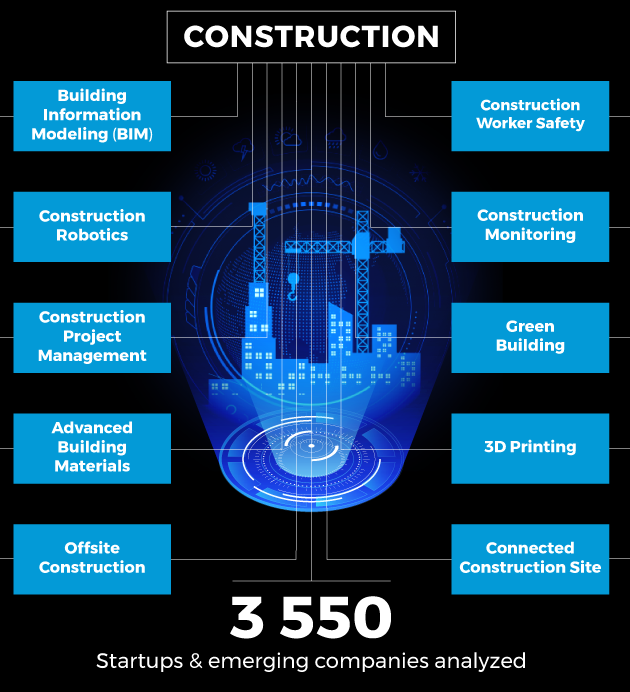

What are the top 10 trends of the Construction Industry?

The COVID-19 pandemic has changed the game of construction industry

and how things operate. There has been a lot of light shed on

technology adoption. To be precise, innovations that enhance

efficiency are being concentrated on.

The traditional Brick-and-Mortar Industry, is being revamped and emerging technologies such as Construction Robotics, 3D Printing and the Conventional Pen and Paper planning is taken over by advanced processes like Digital Project Management and Building Information Modelling (BIM).

Before getting a deep dive into these trends lets understand what has made the construction industry hop on these trends.

There are emerging new requirements everyday that require modern and efficient solutions.The construction industry and technology have several complementary facets, which include:Rapidly Changing Client Expectations.

Powerful Capacities in Technologies.

Burgeoning Start-up Environment.

Emerging Techies and New Gen Craftsmen.

Supportive Legal Frameworks.

Now, let’s understands these trends in detail.

What is BIM?

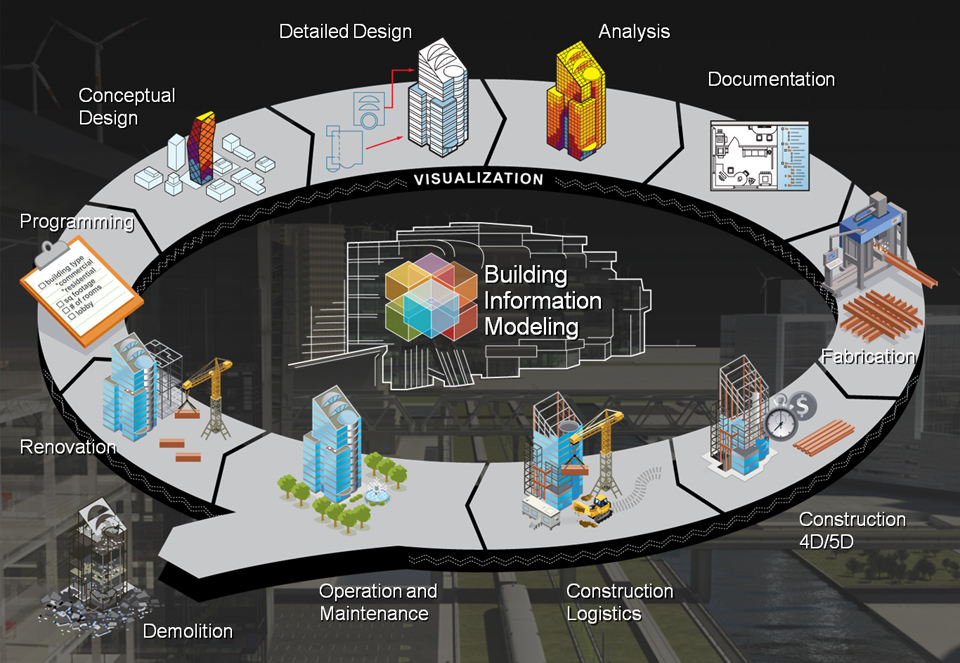

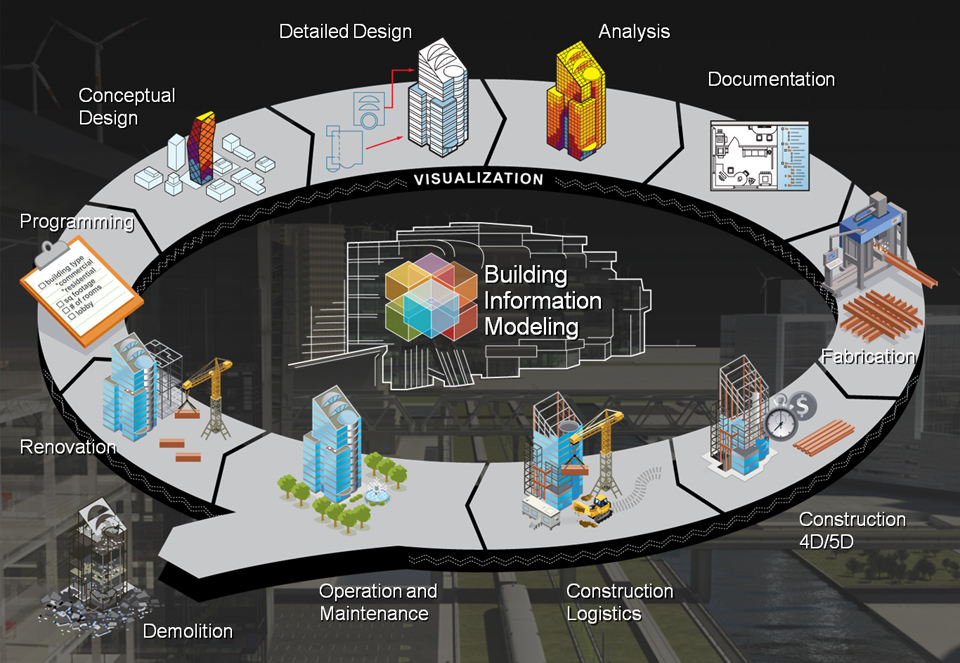

Building Information Modeling famously known as BIM has already revolutionized the Construction Industry. BIM presents Architecture, Engineering and Construction ( AEC ) into Digitalization. It cohesively clusters multi-factored data to generate a digitalized representation for the built asset.

BIM has a well structured process that enables design and construction teams to increase their productivity and be time efficient.

It allows them to have a note of the data that is created during the process, analyze them and to better their operations and maintenance activities.

It allows us to handle and overcome issues like over costs, redundancy, QC Issues and project delays and makes the entire process much easier.

The most recent version of BIM is known as the 5D BIM, it enables the construction team to have shorter project cycles, increase in productivity and a better project scope understanding.

Now that we know that BIM is extremely supporting factor to productivity of the project, let’s understand it’s advantages.

What are the advantages of BIM?

A few advantages of BIM over conventional construction methods can be listed as follows:

Increased control over the project.

Reduces tedious work of information production and redundancy.

Automates construction production management.

Higher build quality.

Increases cost efficiency by decreasing planning issues.

Easier to overview and maintain.

Increased collaboration across build teams through all phases of

the project.

Reduces time delays.

What is Construction Robotics?

Construction is known to be one of the most labor-intensive industry in the world. It also calls for repetitive and time-consuming procedures.

Construction Robotics are used to automate workflow that was previously done manually.

Robots and automated machinery do not have the problems of fatigue, burnout or lack of interest in a repeated and redundant process.

How does Construction Robots make the process easier?

More concretely, an example directly related to the industry includes robotics solutions that automate heavy equipment and fleets for excavation, transportation, load lifting, concrete work, and demolition. At the same time, advanced building techniques are also taking advantage of robotics and machine assisted solutions for activities like industrialized construction and 3D printing.

Since it’s evident that Construction Robots make the project building process easier, let’s get to know it’s advantages.

What are the advantages of Construction Robots?

Construction Robots performs as an allrounder and helps reduce the manual interference and hard work involved. But if we want to understand its advantages, the significant advantages of construction robotics can be listed down as follows:

Process simplification.

Data digitalization to improve decision making.

Automation to facilitate management tasks.

Delivering more efficiency and accuracy.

Shrinking operating costs and wastage.

Can be programmed to meet specific needs.

Creates safer work environments.

Meeting industry demands and labor shortages.

Producing high levels of productivity.

What is Construction Monitoring and why is it important?

Construction monitoring can be explained as a collection of independent inspections tracking the overall quality of the build asset and the progress of construction.

Areas to monitor mostly include:

The construction environment

Quality control

Timeliness and meeting targets

Negotiations, suppliers and supplier performance

Health and safety

Costings

Materials

Conformance with plans and specifications

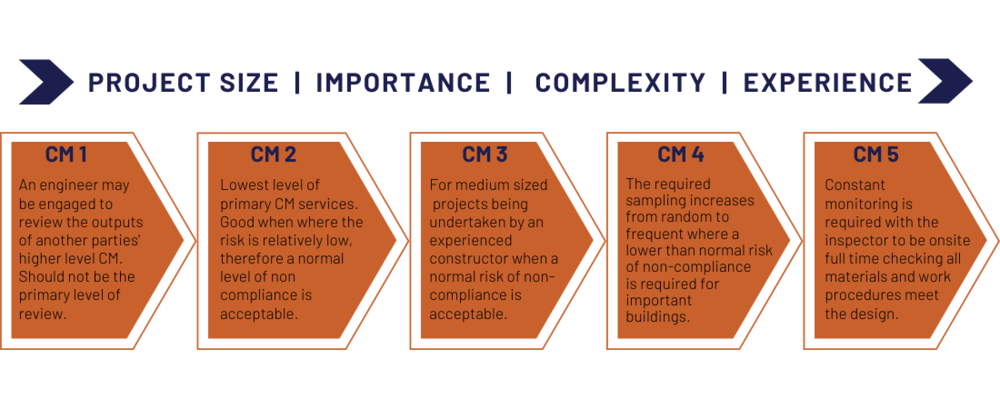

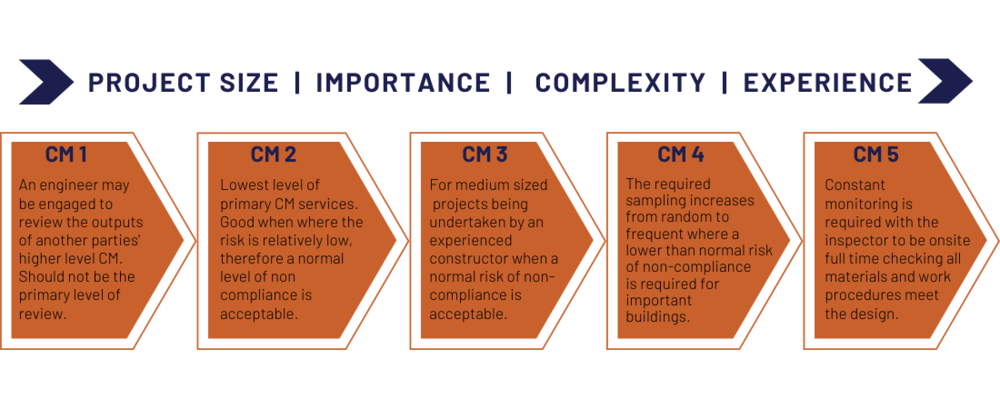

What are the levels of Construction Monitoring?

The level of Construction Monitoring chosen will determine the value added to the project.

The CM level varies from project to project, and factors such as project size, importance, complexity and the skill or experience of the constructor will play a part in which level is chosen. However, to have the confidence that as-built construction meets all it’s contractual requirements may require more in depth Construction Monitoring.

What are the advantages of Construction Monitoring?

Apart from the fact that it improves the overall process of building an asset, few more advantages of construction monitoring are:

Maximizes communication and minimizes conflict.

There exists a central point of communication, control and

responsibility.

Saves considerable amount of time and money.

Real time tracking.

Stakeholder collaboration.

Improvement of productivity.

Real time suggestions and recommendations.

What are advanced building materials?

Advanced Building Materials are making new Construction More Sustainable.

Construction Materials that are most commonly known are wood, concrete, bricks etc. These materials have competition from new and innovative materials in recent times.

These new materials present us with different advantages from eco-friendly manufacturing to sleek contemporary designs.

Why should we use Advanced Building Materials?

According to Let’s Build, the much awaited and anticipated revolution in construction is gaining momentum. We now have drones, virtual reality, augmented reality, BIM, project management and more. But it doesn’t stop here! Researchers and various institutes are taking technology to the next level. Development in concrete and various other construction materials has been aggressive and intense.

As a result, the construction industry has managed to offer a very convincing answer to the burning question of how modern construction materials could look like in the near future.

What Advanced Building Materials are currently used in the market?

Emerging technologies made possible a change in the field of construction. Here are the 11 advanced construction materials used currently in the market.

3-D printed graphene

Light-generating concrete

Liquid granite

Translucent wood

Cross laminated Timber

Self-healing concrete

Transparent aluminum

Flexible Concrete

These sound tech-y and extremely ground breaking when used but let’s

understand their advantages in real time.

What are the advantages of the Advanced Building Materials?

Few of the significant advantages of advanced building materials that can be listed down are as follows:Faster construction

Fewer housing defects

Reduces energy and time wastages

Sustainable

Safe and secure

What is a Green Building?

According to US Environmental Protection Agency (US EPA), a Green building is the practice of creating structures and using processes that are environmentally responsible and resource-efficient throughout a building's life-cycle from siting to design, construction, operation, maintenance, renovation and deconstruction. This practice expands and complements the classical building design concerns of economy, utility, durability, and comfort. Green building is also known as a sustainable or high performance building.

What are the features of Green Building?

There are a number of features which can make a building ‘green’. These include:

Efficient use of energy, water and other resources

Use of renewable energy, such as solar energy

Pollution and waste reduction measures, and the enabling of re-use

and recycling

Good indoor environmental air quality

Use of materials that are non-toxic, ethical and sustainable

Consideration of the environment in design, construction and

operation

Consideration of the quality of life of occupants in design,

construction and operation

A design that enables adaptation to a changing environment

Why should we consider Green Buildings?

According to USI, in recent years, more and more professionals have been focusing on energy efficiency in a variety of industries. Studies show that the development and long-term growth of larger communities has had a major impact on the surrounding natural environment. As such, experts are beginning to focus on the design, construction and large-scale manufacturing of green buildings that could provide individuals with a more responsible way to consume natural resources. Not only does the widespread functionality of green buildings improve the local environment, but those working and living inside the buildings can enjoy healthier atmospheres, free of unnecessary pollution and waste.

These facts makes it evident that we should consider Green Buildings more often. Now let’s understand it’s major advantages that makes it eco-friendly and sustainable.

What are the advantages of Green Buildings?

The advantages of Green Buildings can be broadly classified into 3 categories. Environmental, Economical and Social benefits.

They can listed down as follows:

What is 3D Printing and how is it used in construction?

Construction 3D printing is a method for manufacturing construction elements or entire buildings by means of a 3D printer printing concrete, polymer, metal, or other materials, layer-by-layer. The most common type of printer is based on a robotic arm that moves back and forth while extruding concrete. Other methods for 3D printing include powder binding and additive welding. Powder binding is 3D printing within a basin of powder, solidifying powder layer-by-layer to create the desired object. Additive welding has been demonstrated by printing a full-scale, functioning metal bridge in Amsterdam.

What are the real time examples of 3D Construction?

All3DP says, Over the last five years, 3D printing technology has produced numerous incredible structures all over the world, including 3D printed houses, cabins, offices, bridges, pavilions, large-scale structures, shelters, and more! As 3D construction grows, it has the potential to disrupt the traditional construction process. With many structures printed in a matter of days, 3D printing shelters, for example, can be beneficial for victims of natural disasters.

Here are a few real time examples of projects that are planned using using 3D Construction and a parameter:

Now that we know there are actually many projects that are being executed with 3d printing technology involved, let us now see what the advantages of it.

What are the advantages of 3D printing in construction?

One of the great things about 3D printing is the design freedom that it offers.

Other than that, here are a few more advantages:

Shorter supply chain and quicker design process

Fewer logistical processes and less waste

Making customized houses available to the wider market

Simpler and more efficient installation of pipes and electrics

What are connected construction sites?

Connected construction refers to a network of construction equipment, vehicles, devices, people, and locations that are all communicating with each other via wireless or digital technology under a single firm or organization.

Another way to think about connected construction is through the lens of information technology. Imagine all of the computers and technological devices in a traditional office, and how they communicate with each other and are monitored by a centralized IT team. Now, add construction vehicles into that mix, and you should have a better idea of how connected construction works.

Where can we use Connected Construction?

The cases where we can use connected constructions are:

Procurement and inventory management

Safety intelligence

Energy management

Asset tracking and performance management

Customer collaboration for design and ideation

Quality sensing or remote inspection

Controls and command center

Dynamic scheduling

Digital win and building information modeling

Why is Connected Construction the future of construction industry?

With connected construction, components work together as a body, ensuring collaboration among stakeholders to improve productivity and efficiency. It automates processes , keeps all stakeholders up to date, and aids in all phases of development, including design, planning, construction, handover, and commissioning. You can also use it while out in the field or the office. As Hewlett Packard writes, “Sensors and tags are used to connect job sites, machines, and workers, allowing for real-time visibility and analytical capabilities for managers… The connected network never sleeps, providing a constant stream of information and analytics to help guide project management.”

Now we have an overview of how Connected Construction has a lot of pros to look forward to. let’s list them out clearly.

What are the advantages of Connected Construction?

Connected Construction enables all the components to work together as a single unit collaboratively. Other than this fact, there are a few other advantages:

Improved communication and transparency.

Real time updates to Minimize risk.

More accurate timelines.

Interoperability between tools eliminating redundancy.

Better and more informed decision making.

Seamless communication and collaboration across all stakeholders.

Reduced construction conflicts and project costs.

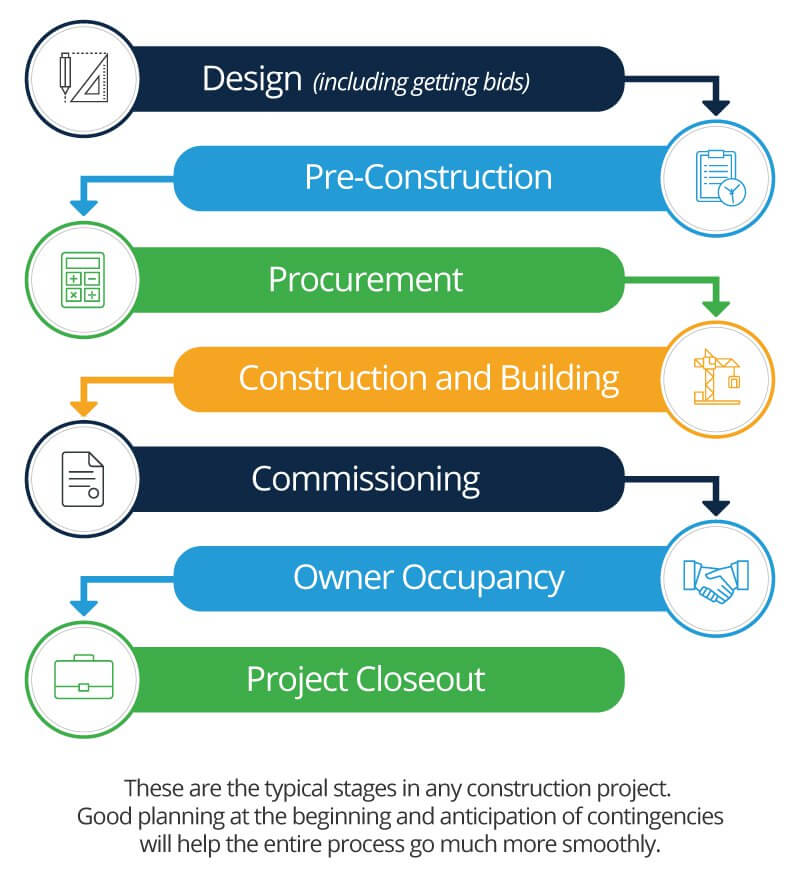

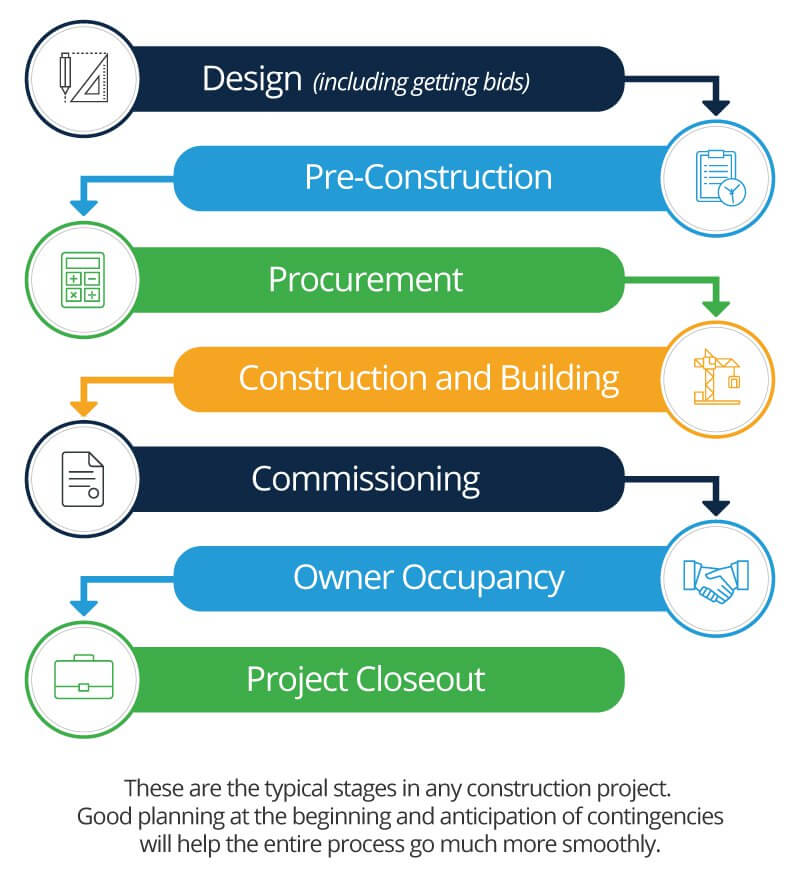

What is construction project management?

In brief, construction management is the process of managing construction projects. When comparing construction project management to other types of projects, the main distinction is that construction is mission-based. That means that the project’s organization ends with the completion of the project build.

Why is construction project management important?

Effective construction project management benefits owners by increasing the potential for successful project completion—on time, within budget, and free of financial or legal complications. Construction management is a professional service that uses specialized project management techniques to oversee the planning, design and construction of a project. While project oversight services evolve over the course of the project, construction management is intended to optimize best industry practices, prudent management decision-making, and effective and transparent project controls and reporting methods.

Construction management is particularly vital to large-scale projects that have more potential for problems that could significantly delay the project and cost money. A construction manager measures each design decision with careful analysis that calculates the impact that decision will make on the budget and schedule. Without a professional construction management team, an unforeseen problem risks derailing the entire project.

Now let’s understand the advantages of the same.

What are the advantages of construction project management?Optimize and accelerate the project schedule

Ensure compliance with the latest regulations and industry

standards

Leadership and centralized communication

Budget Management and accounting

Document sharing and control

What is Construction Worker Safety?

According to United States Department of Labor, Construction is a high hazard industry that comprises a wide range of activities involving construction, alteration, and/or repair. Construction workers engage in many activities that may expose them to serious hazards, such as falling from rooftops, unguarded machinery, being struck by heavy construction equipment, electrocutions, silica dust, and asbestos.

The information, tools, and resources provided in these Construction Industry web pages are designed to assist those in the industry - whether worker or employer - to identify, reduce, and eliminate construction-related hazards.

What are the common causes the reduction of worker’s safety at a construction site?

Tool misuse

Trenches

Electrical sources

Poorly structured construction site rules and regulations

Powerful industry vehicles

Excavations and hazardous gases

Confined spaces

Fire and emergencies

Why is Construction Worker Safety important?

Clock Shark says that, if your worksites are not safe, neither are your workers, and neither is your company. Construction has a notoriously high level of difficulty finding skilled workers, and it’s crucial to protect the ones you have.

Having safety regulations also protects the public, since many construction projects are in populated areas.

But physical safety is not the only reason it’s important on your worksites.

You need a high level of safety standards for jobs that require bonding. And you’re much more likely to get such contracts if you have a positive and credible reputation in the industry.

Plus, you’ll save money. Your Experience Modification Rate (EMR) establishes the costs of your annual construction insurance. Insurance companies use your EMR to determine how much risk your company is.

What can we do to protect workers at construction sites?

All employers have a responsibility in protecting the health and safety of their staff, regardless of their occupation or industry. For construction workers, who are exposed to high risk environments, there are additional dangers which must be considered.

Ways we can keep our Construction site safe are:

Start with safety training

Minimize and manage risk

Site security

Safe work method assessment

Use clear signage throughout the site

Entry and exit points

Compliant chemical storage

Environmental conditions

First aid

Providing personal protective (PPS) equipment

Dropped objects

What is Offsite Construction and what are its types?

Offsite construction is a process that involves the planning, designing, fabricating, and transportation of fabricated building components and their subsequential installation on site. Offsite construction increases construction productivity, reduces jobsite congestion and the associated safety risks, increases quality, and reduces construction schedules.

When can Offsite Construction be used?

Offsite construction is excellent for projects that meet the following criteria:Working under pressure

The Jobsite is plagued by inclement weather

The construction of the building necessitates repeating internal

structures

Limited space on the Jobsite

Theft and vandalism-related risks and issues

Building height, intense heat, and cold pose safety hazards

What are the advantages of Offsite Construction?

Offsite construction is a growing trend, with many companies growing wise to the advantages of moving the building process away from the physical site and into a controlled factory environment. Here, we take a look at some of the reasons why offsite is the next big thing.

Here are a few advantages of Offsite Construction:Efficiency and predictability

Safety

Sustainability

Less labor

Less training

No disruption to residents

The traditional Brick-and-Mortar Industry, is being revamped and emerging technologies such as Construction Robotics, 3D Printing and the Conventional Pen and Paper planning is taken over by advanced processes like Digital Project Management and Building Information Modelling (BIM).

Before getting a deep dive into these trends lets understand what has made the construction industry hop on these trends.

What is the need of adapting new trends?

There are emerging new requirements everyday that require modern and efficient solutions.The construction industry and technology have several complementary facets, which include:

Now, let’s understands these trends in detail.

What are the current trends in Construction?

1. Building Information Modelling (BIM)

What is BIM?

Building Information Modeling famously known as BIM has already revolutionized the Construction Industry. BIM presents Architecture, Engineering and Construction ( AEC ) into Digitalization. It cohesively clusters multi-factored data to generate a digitalized representation for the built asset.

BIM has a well structured process that enables design and construction teams to increase their productivity and be time efficient.

It allows them to have a note of the data that is created during the process, analyze them and to better their operations and maintenance activities.

It allows us to handle and overcome issues like over costs, redundancy, QC Issues and project delays and makes the entire process much easier.

The most recent version of BIM is known as the 5D BIM, it enables the construction team to have shorter project cycles, increase in productivity and a better project scope understanding.

Now that we know that BIM is extremely supporting factor to productivity of the project, let’s understand it’s advantages.

What are the advantages of BIM?

A few advantages of BIM over conventional construction methods can be listed as follows:

2. Construction Robotics

What is Construction Robotics?

Construction is known to be one of the most labor-intensive industry in the world. It also calls for repetitive and time-consuming procedures.

Construction Robotics are used to automate workflow that was previously done manually.

Robots and automated machinery do not have the problems of fatigue, burnout or lack of interest in a repeated and redundant process.

How does Construction Robots make the process easier?

More concretely, an example directly related to the industry includes robotics solutions that automate heavy equipment and fleets for excavation, transportation, load lifting, concrete work, and demolition. At the same time, advanced building techniques are also taking advantage of robotics and machine assisted solutions for activities like industrialized construction and 3D printing.

Since it’s evident that Construction Robots make the project building process easier, let’s get to know it’s advantages.

What are the advantages of Construction Robots?

Construction Robots performs as an allrounder and helps reduce the manual interference and hard work involved. But if we want to understand its advantages, the significant advantages of construction robotics can be listed down as follows:

3. Construction Monitoring

What is Construction Monitoring and why is it important?

Construction monitoring can be explained as a collection of independent inspections tracking the overall quality of the build asset and the progress of construction.

Areas to monitor mostly include:

What are the levels of Construction Monitoring?

The level of Construction Monitoring chosen will determine the value added to the project.

The CM level varies from project to project, and factors such as project size, importance, complexity and the skill or experience of the constructor will play a part in which level is chosen. However, to have the confidence that as-built construction meets all it’s contractual requirements may require more in depth Construction Monitoring.

What are the advantages of Construction Monitoring?

Apart from the fact that it improves the overall process of building an asset, few more advantages of construction monitoring are:

4. Advanced Building Materials

What are advanced building materials?

Advanced Building Materials are making new Construction More Sustainable.

Construction Materials that are most commonly known are wood, concrete, bricks etc. These materials have competition from new and innovative materials in recent times.

These new materials present us with different advantages from eco-friendly manufacturing to sleek contemporary designs.

Why should we use Advanced Building Materials?

According to Let’s Build, the much awaited and anticipated revolution in construction is gaining momentum. We now have drones, virtual reality, augmented reality, BIM, project management and more. But it doesn’t stop here! Researchers and various institutes are taking technology to the next level. Development in concrete and various other construction materials has been aggressive and intense.

As a result, the construction industry has managed to offer a very convincing answer to the burning question of how modern construction materials could look like in the near future.

What Advanced Building Materials are currently used in the market?

Emerging technologies made possible a change in the field of construction. Here are the 11 advanced construction materials used currently in the market.

What are the advantages of the Advanced Building Materials?

Few of the significant advantages of advanced building materials that can be listed down are as follows:

5. Green Building

What is a Green Building?

According to US Environmental Protection Agency (US EPA), a Green building is the practice of creating structures and using processes that are environmentally responsible and resource-efficient throughout a building's life-cycle from siting to design, construction, operation, maintenance, renovation and deconstruction. This practice expands and complements the classical building design concerns of economy, utility, durability, and comfort. Green building is also known as a sustainable or high performance building.

What are the features of Green Building?

There are a number of features which can make a building ‘green’. These include:

Why should we consider Green Buildings?

According to USI, in recent years, more and more professionals have been focusing on energy efficiency in a variety of industries. Studies show that the development and long-term growth of larger communities has had a major impact on the surrounding natural environment. As such, experts are beginning to focus on the design, construction and large-scale manufacturing of green buildings that could provide individuals with a more responsible way to consume natural resources. Not only does the widespread functionality of green buildings improve the local environment, but those working and living inside the buildings can enjoy healthier atmospheres, free of unnecessary pollution and waste.

In the United States, buildings account for:

39% of total energy use

68% of total electricity consumption

30% of landfill waste

38% of carbon dioxide emissions

12% of total water consumption

These facts makes it evident that we should consider Green Buildings more often. Now let’s understand it’s major advantages that makes it eco-friendly and sustainable.

What are the advantages of Green Buildings?

The advantages of Green Buildings can be broadly classified into 3 categories. Environmental, Economical and Social benefits.

They can listed down as follows:

-

Environmental benefits of green building:

- Enhance and protect biodiversity and ecosystems

- Improve air and water quality

- Reduce waste streams

- Conserve and restore natural resources

-

Economic benefits of green building:

- Reduce operating costs

- Improve occupant productivity

- Enhance asset value and profits

- Optimize life-cycle economic performance

-

Social benefits of green building:

- Enhance occupant health and comfort

- Improve indoor air quality

- Minimize strain on local utility infrastructure

- Improve overall quality of life

6. 3D Printing

What is 3D Printing and how is it used in construction?

Construction 3D printing is a method for manufacturing construction elements or entire buildings by means of a 3D printer printing concrete, polymer, metal, or other materials, layer-by-layer. The most common type of printer is based on a robotic arm that moves back and forth while extruding concrete. Other methods for 3D printing include powder binding and additive welding. Powder binding is 3D printing within a basin of powder, solidifying powder layer-by-layer to create the desired object. Additive welding has been demonstrated by printing a full-scale, functioning metal bridge in Amsterdam.

What are the real time examples of 3D Construction?

All3DP says, Over the last five years, 3D printing technology has produced numerous incredible structures all over the world, including 3D printed houses, cabins, offices, bridges, pavilions, large-scale structures, shelters, and more! As 3D construction grows, it has the potential to disrupt the traditional construction process. With many structures printed in a matter of days, 3D printing shelters, for example, can be beneficial for victims of natural disasters.

Here are a few real time examples of projects that are planned using using 3D Construction and a parameter:

Icon takes its first (of a few) spot on our list with its

ambitious announcement to 3D print

100 homes in Austin, Texas. Working with leading homebuilding company Lennar, Icon plans to

break ground on the housing development in 2022.

Icon’s innovative Vulcan construction system, which will be used for this project, can rapidly create buildings of up to 3,000 square feet. The manufacturing method produces homes that are resilient, energy-efficient, and built to the International Building Code (IBC) structural code standard.

Icon’s innovative Vulcan construction system, which will be used for this project, can rapidly create buildings of up to 3,000 square feet. The manufacturing method produces homes that are resilient, energy-efficient, and built to the International Building Code (IBC) structural code standard.

Habitat for Humanity delivered an amazing Christmas present in

2021 by opening their

first 3D printed home to occupants

in December. The charitable organization partnered with Alquist to

print the concrete single-level home.

Offering the home to low-income families who volunteer with the organization is further proof of the technology’s massive cost savings, while this project also serves as Alquist’s proof of concept to move forward with their large-scale Project Virginia plans.

Offering the home to low-income families who volunteer with the organization is further proof of the technology’s massive cost savings, while this project also serves as Alquist’s proof of concept to move forward with their large-scale Project Virginia plans.

SQ4D generated their own flurry of headlines when they listed this

Riverhead New York home on the market. That’s because it’s the

first 3D printed house

authorized to be sold commercially

in the United States.

While many builders are bragging about the potential of 3D printed homes, SQ4D put their money where their mouth is by listing it on Zillow for 50% below the price of comparable homes in the area, proving the much-talked-about benefits of 3D printing construction.

While many builders are bragging about the potential of 3D printed homes, SQ4D put their money where their mouth is by listing it on Zillow for 50% below the price of comparable homes in the area, proving the much-talked-about benefits of 3D printing construction.

Now that we know there are actually many projects that are being executed with 3d printing technology involved, let us now see what the advantages of it.

What are the advantages of 3D printing in construction?

One of the great things about 3D printing is the design freedom that it offers.

Other than that, here are a few more advantages:

7. Connected Construction Site

What are connected construction sites?

Connected construction refers to a network of construction equipment, vehicles, devices, people, and locations that are all communicating with each other via wireless or digital technology under a single firm or organization.

Another way to think about connected construction is through the lens of information technology. Imagine all of the computers and technological devices in a traditional office, and how they communicate with each other and are monitored by a centralized IT team. Now, add construction vehicles into that mix, and you should have a better idea of how connected construction works.

Where can we use Connected Construction?

The cases where we can use connected constructions are:

Why is Connected Construction the future of construction industry?

With connected construction, components work together as a body, ensuring collaboration among stakeholders to improve productivity and efficiency. It automates processes , keeps all stakeholders up to date, and aids in all phases of development, including design, planning, construction, handover, and commissioning. You can also use it while out in the field or the office. As Hewlett Packard writes, “Sensors and tags are used to connect job sites, machines, and workers, allowing for real-time visibility and analytical capabilities for managers… The connected network never sleeps, providing a constant stream of information and analytics to help guide project management.”

Now we have an overview of how Connected Construction has a lot of pros to look forward to. let’s list them out clearly.

What are the advantages of Connected Construction?

Connected Construction enables all the components to work together as a single unit collaboratively. Other than this fact, there are a few other advantages:

8. Construction Project Management

What is construction project management?

In brief, construction management is the process of managing construction projects. When comparing construction project management to other types of projects, the main distinction is that construction is mission-based. That means that the project’s organization ends with the completion of the project build.

Why is construction project management important?

Effective construction project management benefits owners by increasing the potential for successful project completion—on time, within budget, and free of financial or legal complications. Construction management is a professional service that uses specialized project management techniques to oversee the planning, design and construction of a project. While project oversight services evolve over the course of the project, construction management is intended to optimize best industry practices, prudent management decision-making, and effective and transparent project controls and reporting methods.

Construction management is particularly vital to large-scale projects that have more potential for problems that could significantly delay the project and cost money. A construction manager measures each design decision with careful analysis that calculates the impact that decision will make on the budget and schedule. Without a professional construction management team, an unforeseen problem risks derailing the entire project.

Now let’s understand the advantages of the same.

What are the advantages of construction project management?

9. Construction Worker Safety

What is Construction Worker Safety?

According to United States Department of Labor, Construction is a high hazard industry that comprises a wide range of activities involving construction, alteration, and/or repair. Construction workers engage in many activities that may expose them to serious hazards, such as falling from rooftops, unguarded machinery, being struck by heavy construction equipment, electrocutions, silica dust, and asbestos.

The information, tools, and resources provided in these Construction Industry web pages are designed to assist those in the industry - whether worker or employer - to identify, reduce, and eliminate construction-related hazards.

What are the common causes the reduction of worker’s safety at a construction site?

1. 1 in 5 deaths among U.S. workers is in the construction industry

2. Of the 42 annual crane-related deaths, around 60% involve a falling object

3. A total of 1,008 construction workers died on the job in 2020

4. Each year, 10.2 of every 100,000 construction workers suffer a fatal injury, which is the third highest rate of any industry

5. Falls account for 34% of all construction deaths — eliminating falls in construction would save more than 300 lives every year

Why is Construction Worker Safety important?

Clock Shark says that, if your worksites are not safe, neither are your workers, and neither is your company. Construction has a notoriously high level of difficulty finding skilled workers, and it’s crucial to protect the ones you have.

Having safety regulations also protects the public, since many construction projects are in populated areas.

But physical safety is not the only reason it’s important on your worksites.

You need a high level of safety standards for jobs that require bonding. And you’re much more likely to get such contracts if you have a positive and credible reputation in the industry.

Plus, you’ll save money. Your Experience Modification Rate (EMR) establishes the costs of your annual construction insurance. Insurance companies use your EMR to determine how much risk your company is.

What can we do to protect workers at construction sites?

All employers have a responsibility in protecting the health and safety of their staff, regardless of their occupation or industry. For construction workers, who are exposed to high risk environments, there are additional dangers which must be considered.

Ways we can keep our Construction site safe are:

10. Offsite Construction

What is Offsite Construction and what are its types?

Offsite construction is a process that involves the planning, designing, fabricating, and transportation of fabricated building components and their subsequential installation on site. Offsite construction increases construction productivity, reduces jobsite congestion and the associated safety risks, increases quality, and reduces construction schedules.

There are different forms through which an offsite construction

can be performed. They are:

1. Volumetric Construction

2. Hybrid Construction

3. Panelized Construction

4. Sub-Assemblies and Accessories Systems

1. Volumetric Construction

2. Hybrid Construction

3. Panelized Construction

4. Sub-Assemblies and Accessories Systems

When can Offsite Construction be used?

Offsite construction is excellent for projects that meet the following criteria:

What are the advantages of Offsite Construction?

Offsite construction is a growing trend, with many companies growing wise to the advantages of moving the building process away from the physical site and into a controlled factory environment. Here, we take a look at some of the reasons why offsite is the next big thing.

Here are a few advantages of Offsite Construction: